Microfarms and Bioreactors

Microfarms and bioreactors in modular systems

Algae are being grown in outdoor ponds, greenhouses, photo bioreactors, fermenters and hybrid systems combining bioreactors and ponds. As new technologies and systems arrive, algae microfarming will be less costly, easier and more accessible for more people around the world. Emerging technology will stimulate a distributed model of scalable growing systems and local community microfarms, growing algae for valuable food and biomedicines for the nearby region.

Some algae like dunaliella are grown in deep saline ponds with little mixing. Algae like spirulina are grown in shallow raceway ponds mixed with a paddlewheel or compressed air that keeps the culture moving around the raceway. This turbulence moves algae cells to the surface where they absorb sunlight. Algae biomass is harvested by microscreen, filter, centrifuge or flocculation.

Raceways scale to any size and have the advantage of simple, low cost construction and maintenance. Most algae production today is in open raceways because ponds are cheap to build and operate. Ponds are more productive in tropical, subtropical and temperate areas with warm temperatures, low rainfall and little cloud cover.

Disadvantages of ponds are lower productivity from lack of temperature control, water loss from evaporation which increases retained salts over time and impacts culture stability. In outdoor ponds it is difficult to control algae predators such as amoeba, ciliates, bacteria, rotifers, viruses, fungi, and zooplankton that can decimate the algae biomass within hours. Open ponds are vulnerable to contamination from dust, windborne organisms, insects, and birds.

Commercial algae producers have strategies to minimize contamination by opportunistic weed algae in open ponds. Producers grow spirulina at high bicarbonate concentrations with high pH and dunaliella in high saline water to discourage competing species. To limit contamination, producers grow chlorella in batches in increasing volumes, until harvesting the entire amount, purging ponds and then restarting batches from clean pure laboratory cultures.

Photobioreactors tubes, flat plates or bags are more capital intensive than outdoor ponds, and been primarily used for higher value algae products. Advantages are growing in cold weather and low light by adding sources of heat and light. Closed systems offer tighter control of contamination from unwanted algae, zooplankton predators, dust and debris. Disadvantages, apart from cost, include overheating in hot climates and the need for cooling, and high cleaning maintenance from fouling.

For all these considerations, new research centers and algae incubators have been testing various pond and photobioreactor systems on a small scale to compare results and develop smarter automation systems. Here are two examples of research incubators:

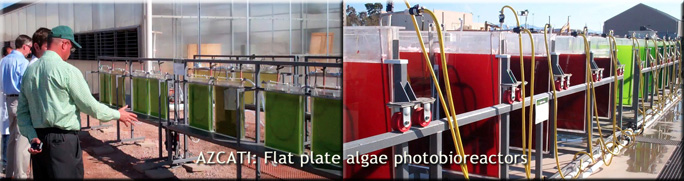

Arizona Center for Algae Technology and Innovation

One of the most impressive research centers is the Arizona Center for Algae Technology and Innovation located at Arizona State University Polytechnic Campus in Mesa Arizona. The AZCATI testbed features raceway ponds and column and flat plate photobioreactors and other novel systems built by NanoVoltaix, an engineering service provider to the cleantech sector. AZCATI serves as a hub for research, testing and commercialization of algae-based products. These include biofuels, pharmaceuticals, nutraceuticals and other algae biomass products.

AZCATI serves as a learning environment for the next generation of scientists and engineers. It provides open test and evaluation facilities for the algae industry and research community. It can assess the performance of individual and combined unit operations across the algae value chain.

Here is a fabulous array of algae technologies from raceway ponds to photobioreactor tubes, bags, plates and hybrid systems growing many species of algae. Production ponds and photobioreactors like these will move into future landscapes, living buildings with green photosynthetic membranes, and into communities for local food and energy.

Algae PARC in Wageningen, Netherlands

The objective of AlgaePARC (Algae Production And Research Centre) is to develop knowledge, technology and process strategies for sustainable production of microalgae as feedstock for fuel, chemicals, food and feed at industrial scale. AlgaePARC allows comparison of different outdoor photobioreactor designs.

The photobioreactors at AlgaePARC were chosen based on state-of-the-art technology and will allow the study of the most important fundamental aspects for the successful operation and scale-up of photobioreactors, such as light regime, mass transfer and photosynthetic efficiency. The systems will be run in parallel and compared on technical, economic and sustainability performance.

The pilot facility comprises four large (24 m2) and three small (2.4 m2) photo-bioreactors. The systems run in parallel and are compared on technical, economic and sustainability performance and results will be used to build up knowledge required for commercial production of microalgae for bulk products.

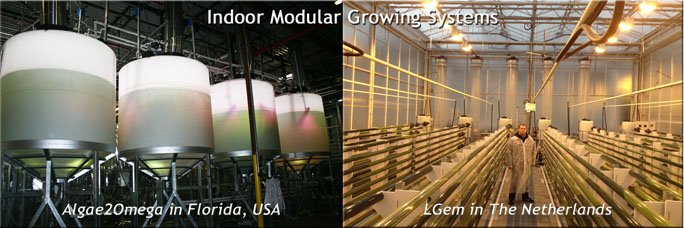

Commercial indoor modular growing systems

Numerous companies around the world are growing algae indoors in photobioreactors. Here are examples of two different approaches, both successfully producing high value algae products.

Algae2Omega is growing haematococcus for astaxanthin in Florida. Inside large warehouses, light is brought inside very large containers using three methods: solartubes bring light from the roof to the surface, solar collectors send light through fiber optic inside the culture, and artificial lighting with LEDs.

LGem is growing nannochloropsis for omega3 in Den Haag, the Netherlands. Inside large high-tech warm greenhouses widely used for growing crops in the Netherlands, sunlight illuminates the algae cultures during sunny days and can be supplemented with artificial lighting during cloudy days and in the off season with shorter days.

Modular aquaponic gardens for cities and rooftops

Urban and community gardens are a rapidly emerging movement for local food production in urban and suburban communities in empty lots, even rooftops. Because algae is so productive in a small area, algae growing systems are ideal for urban gardens and containerized systems for growing food.

Shipping containers have been redesigned for modular housing, offices and health clinics. Now they are being transformed into container gardens with controlled environmental systems. With a 20 foot shipping container and a greenhouse on the roof or sides, a tiny urban farm would help supply a small community. This urban agriculture system can be placed anywhere for create local, sustainable, fresh food that also tastes better.

Containers have advantages. They are available, inexpensive and durable, uniform in dimension, easy to insulate, and stackable, easy to transport and set up. Each build-out is a repeatable process, which leads to efficiencies and economies of scale. Here are some examples of container gardens:

Rostlaube fish and vegetable farm by UrbanFarmers AG (urbanfarmers.ch) combines aquaponics with hydroponics. A mutual support system uses microbe-powered biological filters to convert fish wastes into fertilizers that plants need to grow in a hydroponic greenhouse. Rostlaube replicated this cycle in a self-contained unit that can be located wherever food is needed. The greenhouse warmth promotes vegetable growth and keeps the fish comfortable below. The lower level has a fish tank with two filter systems, recycling all water, with water added only to make up for evaporation.

The ArkFab (arklab.org) is a vertical farm for mushroom cultivation. A repurposed shipping container has an estimated lifetime of 10 years, reducing annual depreciation expense, provides easier installation and relocation of the facility, and allows stacking to use up valuable real-estate. The logistics and shipping industry is familiar with how to move these containers around the globe, so containerized urban agriculture systems can be transported to post-disaster recovery areas.

PodPonics Urban Agriculture (podponics.com) converts used shipping containers into modular controlled-environment growth pods. Controlled environments and LEDs allow plants to thrive. PodPonics crops use 90% less water than traditional farms, no pesticides, less fertilizer, and go from harvest to plate in a few hours. PodPonics urban agriculture creates local, sustainable, fresh food that also tastes better.

For modular growing systems, a variety of algae controlled cultivation systems are being developed for food and higher value products.

Next: Future visions of living algae systems in daily life

How will growing algae change the world and improve our lives? Imagine our future living in cities where buildings are covered with photosynthetic skins and vertical gardens, collecting the sun’s energy and producing food and energy for urban citizens. The International Algae Competition challenged people around the world to design our future with algae food and energy systems. Let’s look into our future and see how algae microfarms could move into landscapes, living buildings with green photosynthetic membranes, and eco communities producing local food and energy.

SPIRULINA

SPIRULINA